Products >> sanitary valves >> sanitary diaphragm valves

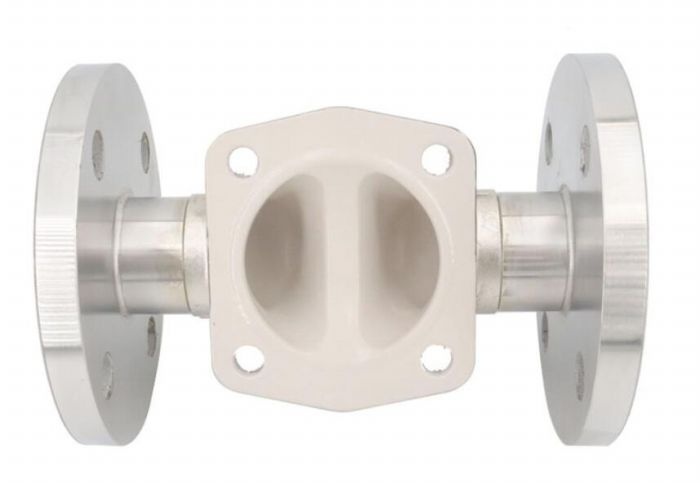

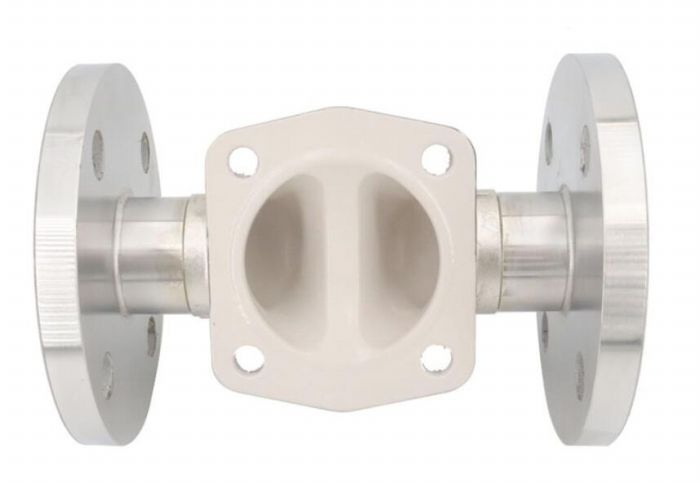

sanitary flange lining fluorine diaphragm valve

- Product No.:202155173052

sanitary flange lining fluorine diaphragm valve

The operation of manual diaphragm valve is very similar to that of hose valve. Rotating the handwheel causes the compressor to drop, starting to push the diaphragm like the bottom wall of the valve body. In throttling state, the manual manipulator rotates to the required flow and stays there. In the on-off state, when the maximum pressure is reached, the two surfaces are tightly sealed. When the diaphragm valve is opened, the rotation effect of the manual manipulator is on the contrary. When the closing element is lifted, the flow area is enlarged. Finally, in the fully open position, the compressor fully retracts into the bonnet with the diaphragm away from the flow. At this point the valve reaches its full area capacity.

The operation of manual diaphragm valve is very similar to that of hose valve. Rotating the handwheel causes the compressor to drop, starting to push the diaphragm like the bottom wall of the valve body. In throttling state, the manual manipulator rotates to the required flow and stays there. In the on-off state, when the maximum pressure is reached, the two surfaces are tightly sealed. When the diaphragm valve is opened, the rotation effect of the manual manipulator is on the contrary. When the closing element is lifted, the flow area is enlarged. Finally, in the fully open position, the compressor fully retracts into the bonnet with the diaphragm away from the flow. At this point the valve reaches its full area capacity.

In short, diaphragm valves provide inherent equal percentage flow characteristics, which tend to move in a straight line during operation.

1. Diaphragm valve switch can not use f wrench, and open to the end, and then close a circle, can not open to the bottom.

2. The screw should be buttered regularly.

3. Do not use too much force when the valve is closed to prevent diaphragm damage.

4. Grease the bolts regularly to prevent rust.

5. After the valve is damaged, it should be disassembled for inspection. If only the diaphragm is damaged, only replace the diaphragm

It's just a movie. When replacing the diaphragm, the valve should be in full open state.

Installation and maintenance

① Before the diaphragm valve is installed, it is necessary to carefully check whether the operating conditions of the pipeline are consistent with the specified scope of use of the valve, and clean the inner cavity to prevent dirt from blocking or damaging the seal

Components.

② Do not brush grease on the rubber lining layer and rubber diaphragm surface to prevent rubber swelling and affect the service life of diaphragm valve.

③ Hand wheel or transmission mechanism is not allowed to be used for lifting, and collision is strictly prohibited.

④ When manually operating the diaphragm valve, do not use the auxiliary lever to prevent excessive torque from damaging the driving parts or sealing parts.

⑤ The diaphragm valve should be stored in a dry and ventilated room. It is strictly forbidden to stack the diaphragm valve

Both ends of the channel must be sealed, and the opening and closing parts should be in the micro open state.

Previous Product:sanitary welded U-type three way diaphragm valve

Next Product:sanitary fluorine lined diaphragm valve